Why the Right Partner Matters as Much as the Right Equipment

When you start looking at custom refrigeration, we’re sure your instinct is to focus on the equipment itself. What temperature can it hold? What is the capacity? What does it cost? These are all reasonable questions, but they only get you part of the way.

How it gets designed, installed, validated, and maintained matters just as much as the components themselves. A freezer that looks great on paper can become a headache if the installation is sloppy, the validation documentation is incomplete, or the service relationship falls apart after the install. On the other hand, a well-designed system from a partner who understands your operation tends to just work, year after year, without creating problems for your team.

When Standard Equipment Does Not Fit

Off-the-shelf freezers work fine for a lot of situations. If you need a standalone unit and your requirements are straightforward, there is nothing wrong with buying from a catalog.

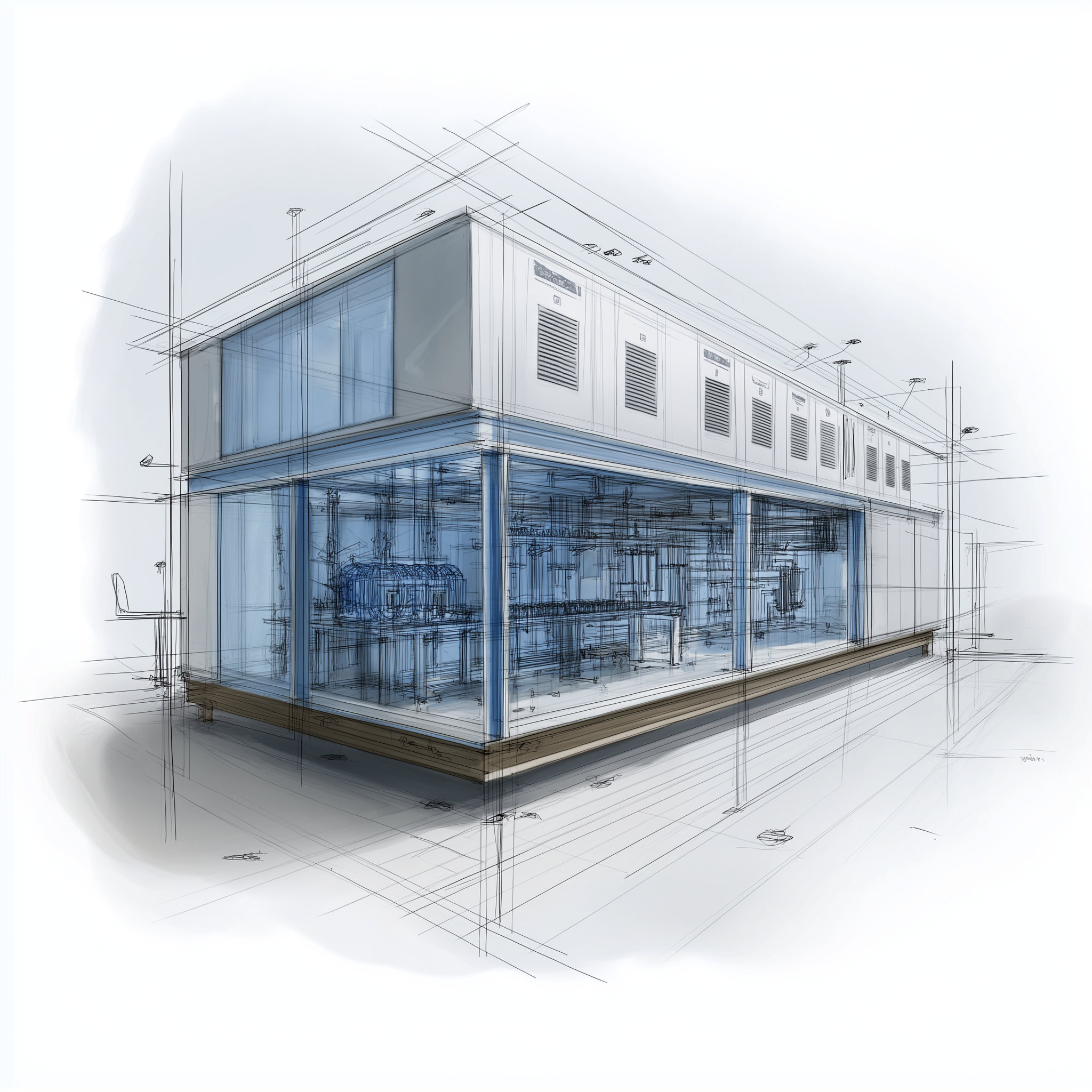

But that approach starts breaking down when you need something more complex. Maybe your facility layout creates space constraints that standard dimensions cannot accommodate. Maybe your capacity needs exceed what standalone units can provide. Maybe you need temperature ranges or uniformity specifications that push beyond what standard products are optimized for.

When you try to make a standard product work in a non-standard situation, you end up with workarounds. You run multiple smaller units instead of a single cohesive system. You bolt on aftermarket monitoring that does not quite integrate properly. Each workaround seems manageable on its own, but they add up, and so does the price tag. More complexity, more maintenance, more things that can go wrong, more documentation to manage.

Custom design is really just about avoiding those compromises. Instead of adapting your operation to fit the equipment, at NWR, we design equipment around what you actually need.

Too Many Vendors

Even when facilities recognize they need something custom, they often end up piecing it together from multiple sources. Equipment from one company, installation from a contractor, validation from a consultant, service from whoever is available locally. It seems reasonable at first… get the best price on each piece and manage the project yourself.

But in practice, this creates headaches that are not immediately obvious until you are on the phone at 11pm dealing with them.

You have to coordinate contractors, you become the project manager making sure the installer understands the equipment specs, the validation team knows what the system is supposed to do. Every handoff between vendors is a chance for something to get lost or miscommunicated, and you are the one who has to catch it.

On top of that, when something goes wrong, accountability gets murky. The equipment manufacturer points at the installer. The installer points at the equipment. The validation consultant says they documented what they found. The service tech says they were never properly briefed on the system. Everyone has a reason why it is not their problem, and you are stuck in the middle trying to get someone to actually fix it. On top of this, institutional knowledge disappears. The people who installed your system are not the people maintaining it. The maintenance team is working from whatever documentation they were given, which may or may not reflect how the system was actually built or why certain decisions were made. When problems come up, they are troubleshooting without the full picture.

What Changes with a Single Partner

When one team handles the whole process, all of these problems go away.

The coordination happens internally. The people designing your system talk directly to the people building it, installing it, and maintaining it. When questions come up during installation, the design team is right there. When validation identifies something that needs adjustment, the install team can address it without multi-vendor negotiation.

Accountability is simple. If something is not right, there is one phone call to make. There is no finger-pointing because there is nobody else to point at. That creates a strong incentive to get things right the first time, and to fix problems quickly when they do occur.

Your records stay together. Equipment specs, installation documentation, validation protocols, maintenance history, service records. All of it comes from the same source and lives in the same place. When you need information, you know where to find it.

And the people maintaining your equipment actually know how it all fits together. They understand the design decisions, the installation details, and the system's history. When something acts up, they are not starting from scratch trying to figure out how it works.

Industry Experience Is Not a “Nice-to-Have”

Regulated environments have requirements that general refrigeration contractors do not always understand. The documentation expectations are different. Validation is not optional.

The consequences when equipment fails are more serious than in a typical commercial application.A partner with real experience in your industry gets this. They know what regulators expect. They understand how to structure validation protocols so they actually hold up during inspections. They know what documentation you need and how to organize it so it is useful rather than just voluminous.

This shows up in the equipment itself. Systems get designed with the right monitoring capabilities built in rather than bolted on. Alarm configurations reflect what the regulations actually require. Components get selected for reliability in environments where the equipment runs continuously and downtime is not acceptable.

It also shows up in service. Technicians who regularly work in regulated facilities know the protocols. They know what they can and cannot touch without approval. They treat the work with the seriousness it deserves.

You can teach a general contractor some of this, but there is no substitute for experience. Someone who has spent years working in plasma facilities and life sciences operations has seen the problems that occur and knows how to prevent them.

That knowledge is hard to replicate with a vendor who is figuring it out as they go.

Why You Should Partner with NWR

None of this is meant to suggest that you should not do your due diligence on equipment specifications and pricing. Those things matter. But they are not the whole picture.

As you evaluate your options, think about what the relationship looks like beyond the initial purchase. Who is going to install this equipment, and do they understand the requirements? Who is going to validate it, and will the documentation hold up? Who is going to maintain it, and do they actually know the system? When something goes wrong at 2 AM, who are you calling?

The answers to those questions tell you a lot about what your experience will actually be like. A good partner makes your life easier, not just at the beginning, but for years afterward. A collection of vendors you have to manage yourself creates ongoing work and ongoing risk.

We think the partnership model is the right approach for custom refrigeration in regulated environments. But more than that, we think these are the right questions to be asking regardless of who you work with. The equipment is important. The relationship around the equipment is just as important.